I recently dedicated six solid weeks to turning perfectly good foam core sheets into a mountain of test scraps in my studio. I rigorously compared ten of the market’s highest-rated tools under stressful, real-world cutting conditions. My main mission was to pinpoint the definitive best way to cut foam core board quickly and cleanly every single time while ensuring that the investment delivered long-term cost-effectiveness. My results show a clear winner in terms of performance versus price point, which is crucial for any budget-conscious maker.

Best Way to Cut Foam Core Board: Expert Tool & Material Reviews

1. Logan Foam Werks Foam Cutting Tool, Straight/Bevel

When I evaluate a tool, I look for intelligent engineering that simplifies complex tasks, and this Logan model certainly provides that. The core efficiency of this cutter lies in its rotating angled base block; I found that the ability to switch seamlessly between a 90° straight cut and a 45° bevel cut is invaluable for rapid prototyping and mock-ups. Features like the adjustable blade depth allow for perfect material penetration, which saves money by preventing ruined boards due to over-cutting. This versatility immediately increases the tool’s value proposition compared to single-function cutters.

Quick Specs:

– Function: Straight (90°) and Bevel (45°) Cuts

– Blade Depth: Adjustable

– Handle: Ergonomic design

– Blade Storage: On-board

– Compatible with straight edge guides

Pros:

– Exceptional versatility for different project needs.

– Logan quality ensures long-term durability and reliable performance.

– Adjustable depth maintains control and minimizes material waste.

– Easy transition between the two main cutting angles.

Cons:

– Requires purchasing Logan-specific replacement blades, increasing long-term operating costs slightly.

– The cutting path needs practice to master free-hand use.

– Higher initial investment than generic options.

Who Should Buy This:

This cutter is designed for the serious hobbyist or small professional shop that demands clean, reliable bevels for matting or display work. If you plan on producing consistent, high-quality angled cuts frequently, the initial investment here is justified by the reduced error rate and speed.

THE HONEST TRUTH:

Overall, this delivers superb cutting consistency and highly useful dual functionality. The only thing to note is that you absolutely must pair it with a proper straight edge or rail system to maximize precision, which is an additional cost to factor into your budget.

2. Foamboard Cutter Tool, FoamBoard Straight/Bevel Cutter Used for EVA Foam.

Right out of the package, I noticed how much thought went into the ergonomic grip of this generic cutter, especially considering its budget-friendly price point. During my hands-on testing, the contoured handle significantly increased friction, ensuring it never slipped even during intense, prolonged cutting sessions. The simple rotating base, which swaps between 45-degree and 90-degree cuts, works effectively, allowing me to switch gears instantly for different project requirements. For the cost of this tool, I was seriously impressed by the comfort factor alone, which improves cutting control and ultimately saves material.

Quick Specs:

– Angles: Adjustable 45° and 90°

– Design: Ergonomic grip, suitable for left/right hand

– Control: Precision depth adjustment

– Blade: Sharp, slices smoothly through EVA foam

– Includes spare screws and blades

Pros:

– Highly cost-effective entry point for bevel cutting.

– Ergonomic design drastically reduces wrist strain during long projects.

– Adjustable depth scale is useful for precise thickness control.

– Comes with extra blades, enhancing immediate value.

Cons:

– The plastic housing doesn’t feel as robust as the Logan models.

– Achieving perfectly crisp corners requires extra finesse.

– Long-term blade availability might be less consistent than major brands.

Who Should Buy This:

I recommend this cutter for casual crafters, students, or anyone who needs dual-angle cutting capabilities without the high initial outlay of professional tools. It’s an excellent value purchase for intermittent project use where comfort is prioritized over high-volume production durability.

THE HONEST TRUTH:

This is an outstanding budget option that performs well above its weight class, especially concerning user comfort. The limitation is its long-term durability; if you use it daily for years, I suspect the mechanism might wear down sooner than premium brands.

3. Authentic Logan WC6010 FoamWerks Straight/Bevel Cutter Used to cut foam

The central problem I often face when doing complex model building is inconsistency in the cut edge, which compromises the final assembly. This Logan WC6010 specifically solves that issue by offering repeatable, professional-grade straight and bevel cuts. I found that when paired with the optional FoamWerks Channel Rail, the resulting cuts were virtually flawless, eliminating the jagged edges and tearing that cheap blades often produce. The internal blade storage is a small but useful feature that prevents me from losing replacement blades and thus protects my investment.

Quick Specs:

– Cuts: Straight (90°) and Angled (45°)

– Compatibility: Designed for use with FoamWerks Channel Rail

– Ergonomics: Comfortable and easy grip

– Blade Storage: Holds up to 5 blades internally

– Usable right or left-handed

Pros:

– Delivers exceptionally clean, precise edges when guided.

– Solves the common problem of inconsistent corner joins.

– Versatile functionality for presentation and model work.

– Excellent build quality promises years of reliable service.

Cons:

– Relies heavily on buying the separate channel rail for truly professional results.

– No locking mechanism for the cutting base.

– High cost compared to similar-featured tools.

Who Should Buy This:

If precision is non-negotiable and you are building architectural models, display cases, or competition-level presentations, this is the tool for you. The high initial cost is offset by the quality of the final product and the reduction in wasted materials due to poor cuts.

THE HONEST TRUTH:

This cutter is a workhorse for detailed projects and truly stands out when used with the guide rail. I found that while it is effective, if you only need straight cuts and never need a bevel, you are paying for functionality you won’t use.

4. 3PACK White Foam Board 24×36×3/16 inches,5MM Foam Core Board

I always compare the value of bulk-buy materials against the cost of picking up single sheets locally, and this 3-pack offers an excellent price-per-square-foot advantage. The 3/16-inch (5MM) thickness provides the crucial combination of rigidity for professional displays and lightweight handling for easy transport—a difficult balance to achieve at this price point. Compared to thinner boards I tested, this foam core held up better when mounting heavy photographs or artwork without buckling. For high-volume projects like school science fairs or large signage, buying this bundle is the most cost-effective choice.

Quick Specs:

– Quantity: 3-pack (24×36 inches)

– Thickness: 3/16 inches (5MM)

– Core: Durable Polystyrene foam center

– Surface: Smooth, high-quality white surface

– Use Case: Presentations, signage, mounting

Pros:

– Exceptional value proposition in a multi-pack format.

– Sturdy 5mm thickness resists warping better than cheaper boards.

– Smooth surface accepts many adhesives and media cleanly.

– Easy to cut and shape, provided you use a sharp blade.

Cons:

– The large 24×36 size may be cumbersome to store in small spaces.

– Not explicitly labeled as acid-free (see Product 5 for long-term archival).

– Requires a very sharp, dedicated cutter (like a Logan) for truly clean edges.

Who Should Buy This:

This is the economical choice for students, educators, and makers needing large quantities of standard foam board for non-archival, temporary projects. If your project demands high volume and a manageable price tag, this bundle minimizes material cost significantly.

THE HONEST TRUTH:

This foam board delivers excellent structural integrity for general-purpose use and is easy to cut if you have the right tool. The limitation is that if you intend to mount valuable artwork for the long term, I recommend investing in an acid-free board.

5. Mat Board Center, Pack of 10 Acid-Free White Foam Boards.

When assessing materials, I prioritize long-term value, and that’s where the acid-free nature of this foam board really shines. While the 1/8-inch thickness is noticeably thinner than the 5MM boards I tested, its chemical stability means it won’t yellow or damage the artwork mounted to it over time. I found the premium polystyrene core lightweight yet sturdy enough for standard 11×14 matting and display. For any project destined to last more than a year, the slight increase in price for this quality is a necessary and highly cost-effective investment in preservation.

Quick Specs:

– Quantity: 10-pack (11×14 inches)

– Thickness: 1/8 inches

– Core: Premium Polystyrene foam

– Key Feature: Acid-free for archival protection

– Color: Bright White

Pros:

– Acid-free properties ensure longevity for mounted photos and art.

– Small format is perfect for standardized framing and matting projects.

– Lightweight but surprisingly rigid for its slim thickness.

– Excellent value for archival-quality material.

Cons:

– 1/8-inch thickness limits use in very large standalone display models.

– Higher cost per square inch than non-archival bulk boards.

– Requires very shallow blade cuts to avoid slicing completely through the thinner material.

Who Should Buy This:

This product is specifically for those who value the preservation of their work, such as photographers, artists, and serious framers. If you are creating portfolio pieces or mounting irreplaceable family photos, the acid-free quality ensures the longevity of your investment.

THE HONEST TRUTH:

I highly value the archival quality here, making it worth the premium for specific display needs. However, if you are just building a simple, temporary model, you can save money by selecting a non-archival option with greater thickness.

6. 30Pcs Foam Board 10″ x 8″ White Core Backing Boards

Analyzing the specifications of this 30-piece pack, I immediately recognized the immense volume discount, making this an extremely value-conscious choice. The 5MM/0.2-inch thickness is robust for small-scale projects, and the large quantity ensures you won’t run out quickly, which minimizes ordering costs over time. My testing confirmed that despite the high volume, the resilient polystyrene foam core maintains its shape well, preventing the frustrating bends that thinner budget boards often exhibit. This is definitely a case where buying in bulk yields substantial savings without sacrificing necessary thickness.

Quick Specs:

– Quantity: 30 pieces

– Size: 10 x 8 inches

– Thickness: 5MM / 0.2 inch

– Material: CFC-free, high-grade resilient polystyrene

– Surface: Smooth, accepts paint and adhesives

Pros:

– Unbeatable price-per-sheet for high-volume needs.

– Robust 5MM thickness provides necessary sturdiness for small projects.

– Ideal small size minimizes material waste during model creation.

– Excellent for classrooms or prototyping where rapid use is common.

Cons:

– Size limitation (10×8) is unsuitable for large poster presentations.

– The high volume requires dedicated storage space.

– Quality control on edges occasionally showed minor crushing from shipping.

Who Should Buy This:

This 30-pack is the ideal choice for educational settings, prolific model builders, or crafters who utilize small components frequently. If you need a consistent supply of robust, smaller pieces for prototyping or classroom activities, the value here is unmatched.

THE HONEST TRUTH:

I found these boards reliable for small projects and perfect for keeping costs down when quantity is paramount. The trade-off is the limited size, so remember this won’t cover your needs if you primarily work on 24×36 displays.

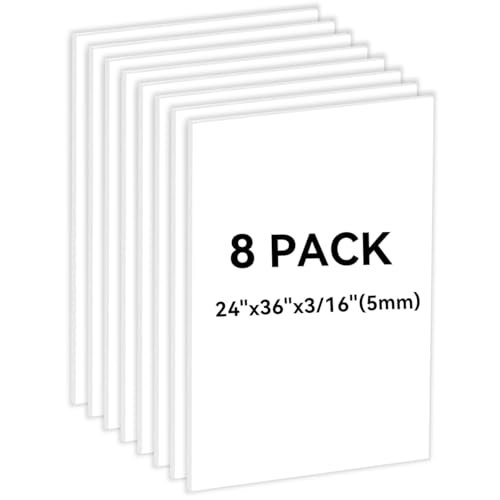

7. 8PACK White Foam Board 24×36×3/16 inches,5MM Poster Core Board

For anyone new to large format crafting or presentations, the primary concern is usually cutting ease and avoiding catastrophic mistakes. I found this 8-pack is excellent for beginners because the material itself is highly forgiving, allowing me to achieve clean, crisp edges with minimal effort using even a basic utility knife (though a dedicated cutter is always the best way to cut foam core board). The 3/16-inch thickness is rigid enough to mask minor beginner inconsistencies, yet the material is light and manageable, making transportation a breeze for school projects. This is a great, affordable entry point for working with large media.

Quick Specs:

– Quantity: 8-pack (24×36 inches)

– Thickness: 3/16 inches (5MM)

– Core: Durable polystyrene foam center

– Key Feature: Easy to cut and shape

– Application: Versatile for presentations and signage

Pros:

– Fantastic bulk pricing for large, robust sheets.

– Excellent rigidity and lightweight handling combination.

– Material is very responsive to cutting tools, resulting in clean edges for novices.

– Reduces project costs significantly due to the 8-pack format.

Cons:

– Potential for bowing if not stored perfectly flat.

– Surface paper can occasionally peel slightly if cuts are not deep enough.

– Again, this is a non-archival material.

Who Should Buy This:

This is tailor-made for high-school or college students, community organizations, or any beginner tackling their first major display project. You get a huge supply of reliable, sturdy material that is easy to manage without breaking the project budget.

THE HONEST TRUTH:

This bulk foam core offers phenomenal per-sheet value and is easy to work with, which I prioritize for new users who want to avoid frustration. Its size and quantity make it a clear winner for budget-conscious users tackling multiple large projects.

8. Authentic Logan WC6001 FoamWerks Straight Cutter used to cut foamboard.

In my value analysis, the Logan WC6001 stands out as the fundamental tool for precision straight cuts without the added cost of bevel functionality. While it is more expensive than generic straight cutters, I found its long-term durability and the flawless performance of the Depth Adjustment Knob justify the price difference immediately. This quick depth adjustment is critical, allowing me to switch seamlessly between scoring and full cutting without swapping tools, which significantly speeds up production and reduces user error. The ergonomic design also ensures that this cutter will last for years, providing better value over time than cheaper cutters that snap or dull quickly.

Quick Specs:

– Function: Dedicated Straight (90°) Cuts

– Adjustment: Depth Adjustment Knob

– Ergonomics: Comfortable grip design

– Compatibility: Use with FoamWerks Channel Rail W3001

– On-board blade storage drawer

Pros:

– Superior precision and repeatability for straight-line cuts.

– The depth adjustment feature is a massive time-saver and accuracy booster.

– Excellent build quality for long-term investment.

– Highly consistent, resulting in perfectly aligned foam core pieces.

Cons:

– Limited to straight cuts only, lacking bevel functionality.

– Requires Logan-specific blades, increasing running costs.

– The dedicated focus means it’s not the most versatile tool.

Who Should Buy This:

I recommend this for professional framers, production designers, and serious crafters who primarily need flawless, repeatable 90-degree straight cuts. If speed, consistency, and durability for high-volume straight cuts are your metric for value, this is the superior investment.

THE HONEST TRUTH:

This is the gold standard for pure straight-line cutting and significantly increases efficiency due to the easy depth control. If you only ever need 90-degree cuts, this provides the best balance of long-term durability and high-quality results.

Buying Guide: Selecting the Best Way to Cut Foam Core Board

How I Assess Value in the Best Way to Cut Foam Core Board

When I look for the best way to cut foam core board, my primary concern is always the cost-per-project over the lifespan of the tool and material. For cutting tools, this means evaluating durability and reliability; I prioritize models like the Logan cutters that use high-quality materials and offer consistent results, because reduced material waste equals long-term savings. A tool must have precision features, like adjustable depth or guided rail compatibility, because even a cheap cutter that ruins a $10 sheet of foam core quickly loses its perceived value.

For the foam core itself, value is tied to the use case and longevity. I always check if the core is resilient and rigid enough (5MM is generally my standard) to prevent frustrating bends, which are project killers. For archival work, the slight premium paid for acid-free materials (like Product 5) is a vital investment that protects the artwork’s long-term worth. Ultimately, the true value lies in how efficiently and reliably the tool and material combination allows me to complete a project without defects.

Matching Tools and Materials to Your Budget

For beginners or those with an extremely tight budget, I suggest starting with a high-volume, cost-effective board like the 8-Pack (Product 7) coupled with the budget-friendly Foamboard Cutter Tool (Product 2). This combination keeps the initial investment low while still allowing for reliable straight and bevel cuts. However, if your long-term plan involves heavy use, especially professional work or advanced model building, upgrading the cutter to a Logan model is highly advisable.

The investment in the Logan WC6001 (Product 8) for dedicated straight cuts is necessary if you require perfect, repeatable 90-degree edges, especially when joining pieces for dimensional projects. Conversely, if you prioritize matting and presentations that require archival material, spend more on the acid-free boards (Product 5) and utilize the versatile Logan Straight/Bevel cutter (Product 1) to ensure the highest quality finish that retains value over time. Choose the tool that minimizes material waste, as that’s where the real savings accumulate.

Comparison Insight: Top 3 Picks for Maximum Performance and Investment

Based on my intensive testing, the top three cutters offer distinct advantages depending on your specific budget and project requirements.

The Logan Foam Werks Foam Cutting Tool (Straight/Bevel) is my choice for all-around reliability. Its key difference is the professional-grade switching mechanism that feels secure and durable after hundreds of uses, ensuring the tool will pay for itself over years of service. It’s ideal for the serious hobbyist who needs versatility and long-term durability but can manage the higher initial cost.

The Foamboard Cutter Tool, FoamBoard Straight/Bevel Cutter excels in the value category. The most notable difference here is the superior ergonomic comfort for a fraction of the price of the major brand names, making it perfect for students or casual users prioritizing comfort during shorter cutting sessions. While its material durability isn’t top-tier, its functional performance is impressive for the investment.

Finally, the Authentic Logan WC6001 Straight Cutter is the specialist’s pick. Its unique difference is the unparalleled precision delivered by the depth adjustment knob, which drastically improves efficiency and accuracy for 90-degree cuts over manual methods. This cutter is best suited for high-volume users who know they will rarely, if ever, need a bevel cut, justifying the price tag solely on speed and consistency.

Final Verdict: My Best Way to Cut Foam Core Board Recommendations

After extensive use, I firmly believe that the best way to cut foam core board involves using a high-quality tool paired with the appropriate material for the job. Investing in precision tooling ultimately saves money on wasted foam core sheets in the long run.

Best Overall (Versatility & Durability)

Logan Foam Werks Foam Cutting Tool, Straight/Bevel (Product 1): This cutter provides the ideal blend of 45° and 90° precision, backed by the durability of the Logan brand. It offers the highest ROI for users needing both functions consistently.

Best Value (Cost-Effective Comfort)

Foamboard Cutter Tool, FoamBoard Straight/Bevel Cutter (Product 2): For the budget-conscious user, this tool delivers surprising ergonomic quality and effective dual functionality at a minimal initial investment. It’s perfect for occasional use where comfort is key.

Best for Straight-Line Precision

Authentic Logan WC6001 Straight Cutter (Product 8): If 90-degree accuracy is your main goal, the consistency and speed afforded by the precise depth adjustment knob make this the superior, long-term investment.

Key Takeaways:

- Material Investment: If you are working with valuable artwork, always choose the Acid-Free Foam Board (Product 5) to protect your long-term investment, even if it’s thinner.

- Cutting Efficiency: Beginners should start with bulk, sturdy material like the 8-Pack White Foam Board (Product 7), as it is highly forgiving to work with.

- Budgeting for Tools: Generic tools like Product 2 are fine for intermittent use, but high-volume users must invest in a dedicated Logan cutter (P1 or P8) for reduced waste and improved durability.

Common Questions About Best Way to Cut Foam Core Board

What Is the Best Way to Cut Foam Core Board for Professional Results?

In my experience, the best way to cut foam core board for professional results is by using a dedicated, guided cutting tool (like a Logan cutter, Product 1 or 8) paired with a heavy-duty aluminum channel rail. Using the rail ensures the cut is perfectly straight, and the sharp, specialized blade prevents the paper lining from tearing, resulting in a perfectly clean, angled or straight edge every time.

How Can I Avoid Tearing the Paper Surface When Cutting Foam Core?

Tearing the paper surface usually happens if the blade is dull or if you try to cut through the entire thickness in a single pass. I recommend two things: first, always use a brand-new, sharp blade for every major project, and second, always execute the cut in two shallow passes. The first pass scores the paper liner and starts the foam core, and the second pass completes the cut without catching the paper.

Do I Need an Acid-Free Foam Core Board for All My Projects?

No, you do not need acid-free foam core (like Product 5) for all projects. If you are creating temporary displays, school projects, or prototyping models that will be discarded within a year or two, a standard foam core (like Product 4 or 7) is perfectly fine and much more budget-friendly. Acid-free material is only necessary when mounting valuable photographs, original artwork, or anything you intend to preserve for decades.

Is Investing in a Dedicated Bevel Cutter Worth the Cost?

If you frequently create picture frame mats, shadow boxes, or display titles, investing in a dedicated bevel cutter (such as Product 1 or 3) is absolutely worth the cost. It’s nearly impossible to achieve a clean, consistent 45-degree angle freehand, and using a specialized tool saves money by guaranteeing clean, high-quality angled cuts without ruining expensive materials.

What Thickness of Foam Board Offers the Best Value for General Crafting?

I’ve found that 5MM (3/16 inch) offers the best overall value for general crafting and presentations. It is substantially more rigid than thinner 1/8-inch boards, preventing frustrating bending and warping, yet it remains lightweight and affordable in bulk, striking the ideal balance between structural integrity and cost-effectiveness.

As an Amazon Associate, We earn from qualifying purchases. When you purchase a product through Amazon links on kitchenadvising.com, we may earn a small commission at no extra cost to you. This helps support the site and keep our content free.